Deformability of soil

The Hollow Test and the True Triaxial Test

Triaxial Test

Triaxial test is the most widely used test method for determining the strength and stress-strain properties of soil.

It is assumed that soil specimen deforms uniformly during the test.

The uniformity of stress and strain in the specimen is the main idea of triaxial test.

However, it is not often the case that a specimen in triaxial apparatus deforms uniformly during the test.

Triaxial Compression Test

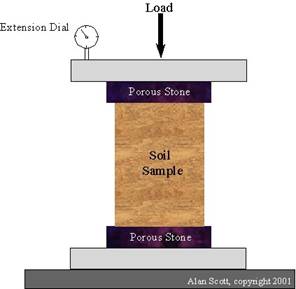

Unconfirmed Compression Test. -An axial load is placed onto a sample, the load is increased until (a) the soil fails, or (b) 15% strain has occurred This load is known as the unconfined compressive strength. There is no lateral support on the soil sample for this measurement.

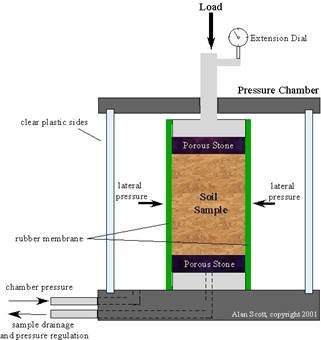

Triaxial Compression Test - Same as the unconfirmed compression test but with the addition of lateral pressure.

Soil Triaxial Cell

FEATURES

- Stainless steel construction

- 1000 kPa (145 psi) capacity

- External cell wall (internal tie rods)

- Top and bottom drainage

- Stiff, low friction loading piston and graphite seal

- External or internal load cells and LVDT’s

- Three standard triaxial cells for 70-mm, 100-mm, and 150-mm specimen diameters

- Available large-scale triaxial cells for testing specimens up to 1,000-mm (40") diameter

Triaxial Soil Testing System

FEATURES

- Closed-Loop Digital Servo Control

- Automatic Data Acquisition, Reduction, & Graphing

- Static and Dynamic Loading

- Pneumatic or Electro-hydraulic

Dynamic triaxial experiment

Thoroughly understanding the behaviour of concrete in dynamic loading is an issue of great significance in civil engineering. However, our knowledge is limited by a lack of dynamic experiment database, especially that collected by dynamic multiaxial tests.

The lateral pressure was maintained at a fixed proportion to the axial load, with the stress ratios of 0:1, 0.25:1, 0.5:1, 0.75:1, 1:1 respectively.

The strain rate varied from 10-5/s to 10-2/s.

From the test results it is revealed that the dynamic strength increases as the strain rate increases, while the damage pattern and the ultimate strength are closely related to the magnitude of lateral pressure exerted on the specimen.

The shapes of stress–strain curves of the specimens at different strain rates are similar to each other. A unified formula is proposed to characterise both the effect of strain rate and the effect of stress ratio on the ultimate strength of concrete in biaxial stress states.