Deformability of soil

The Hollow Test and the True Triaxial Test

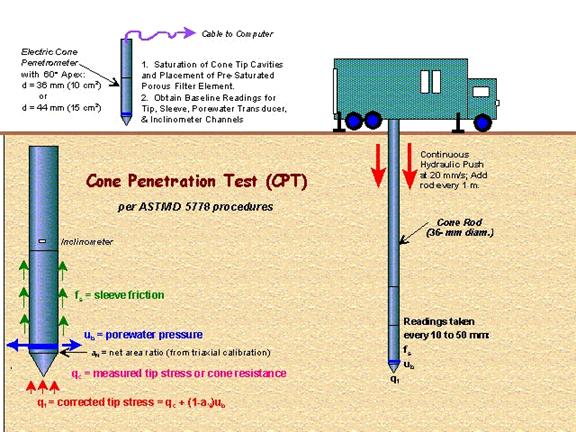

Cone penetration test ( CPT)

The cone penetration test (CPT) is an in situ testing method used to determine the geotechnical engineering properties of soils and delineating soil stratigraphy. Based on this history it has also been called the "Dutch cone test".

A simple, but very effective method of soil investigation consists of pushing a steel rod into the soil, and then measuring the force during the penetration, as a function of depth. This force consists of the reaction of the soil at the point (the cone resistance),and the friction along the circumference of the rods. The method was developed in the 1930’s in the Netherlands. It was mainly intended as an exploration tool, to give an indication of the soil structure, and as a modelling tool for the design of a pile foundation.

Today, the CPT is one of the most used and accepted insitu test methods for soil investigation worldwide.

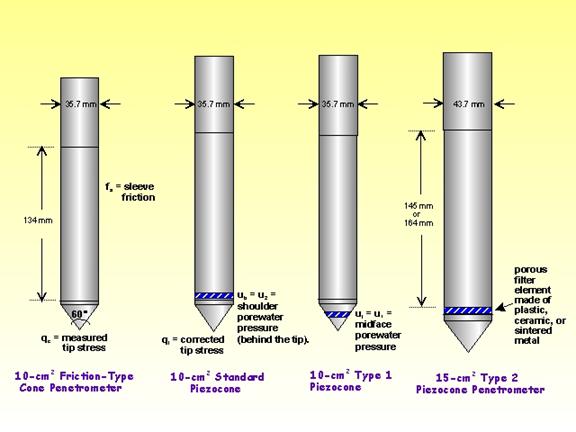

The test method consists of pushing an instrumented cone tip first into the ground at a controlled rate (usually 2 centimeters/second). The resolution of the CPT in delineating stratigraphic layers is related to the size of the cone tip, with typical cone tips having a cross-sectional area of either 10 or 15 cm², corresponding to diameters of 3.6 and 4.4 cm.

The instrument consists of three movable parts, with a common central axis. The upper part is connected, by a screw thread, to a hollow rod,

that reaches to the soil surface, using extension rods of 1 meter length.

The procedure was that pressure was alternately exerted upon the central axis or the outer rods. When pushing on the internal axis at first only the cone is pushed into the ground, over a distance of 35 mm.

The other two parts do not move with respect to the soil (by the friction of the soil), so that the force represents the cone resistance only. When pushing the instrument beyond a distance of 35 mm the second part,

the friction sleeve, moves with the cone, so that in this stage the force

consists of the cone resistance plus the friction along the friction sleeve.

The upper part of the instrument is still stationary in this stage. If it is assumed that the cone resistance is still the same as before, the sleeve friction can be determined by subtraction. If in the next step the force is

exerted on the outer rods, the cone remains stationary and the system is compressed to its original state, but at a greater depth (10 cm). The diameter of the lowest part of the sleeve, which is attached to the cone and moves with it, was sometimes reduced, to ensure that in the first stage only point resistance is measured.

The early applications of CPT mainly determined the soil geotechnical property of bearing capacity. The original cone penetrometers involved simple mechanical measurements of the total penetration resistance to pushing a tool with a conical tip into the soil.

'Friction sleeve' is hydraulically pushed into the ground at a constant speed (ranging form 1.5 to 2.5 cm/s). The force required to maintain this penetration rate, and the shear force acting on the friction sleeve are recorded.

The friction ratio (cone resistance / side friction) gives an indication of the soil type.

Cone Resistance qc = Fc / Ac

Side Friction fs = Fs / As

Friction Ratio Rf = fs / qc

Where Fc = pushing force, Ac = cone plan area, Fs = shear force on friction sleeve, As = area of friction sleeve.

Soil type |

Friction ratio |

Cone resistance qc |

sand, medium – coarse |

0.4% |

|

sand, fine – medium |

0.6% |

5 - 30 MPa |

sand, fine |

0.8% |

|

sand, silty |

1.1% |

|

sand, clayey |

1.4% |

5 - 10 MPa |

sandy clay or loam |

1.8% |

|

silt |

2.2% |

|

clay, silty |

2.5% |

|

clay |

3.3% |

0.5 - 2 MPa |

clay, peaty |

5.0% |

|

peat |

8.1% |

0.1 - 1 MPa |

Table - Friction ratio and cone resistance

Figure - Result of CPT.

A CPT device consists in a cylindrical probe with a cone-shaped tip with different sensors that allow a real time continuous measurement of soil strength and characteristics by pushing it into the ground at a speed of 2 cm/s. The typical CPT probe measures the stress on the tip, the sleeve friction and the porewater pressure. Some of them are equiped with a geophone in order to be able to perform shear wave velocity measurements.

The cone penetration test is in the Netherlands also used as a model test for estimating the bearing capacity of pile foundations. In the west of the country generally about 10 m to 20 m of soft soil layers lay on top of a stiff sand layer, which is excellent for using pile foundations. The bearing capacity of a pile depends mostly on the capacity of the sand layer. The capacity of the tip of the pile with area A can

be estimated by:

Ftip = qcA